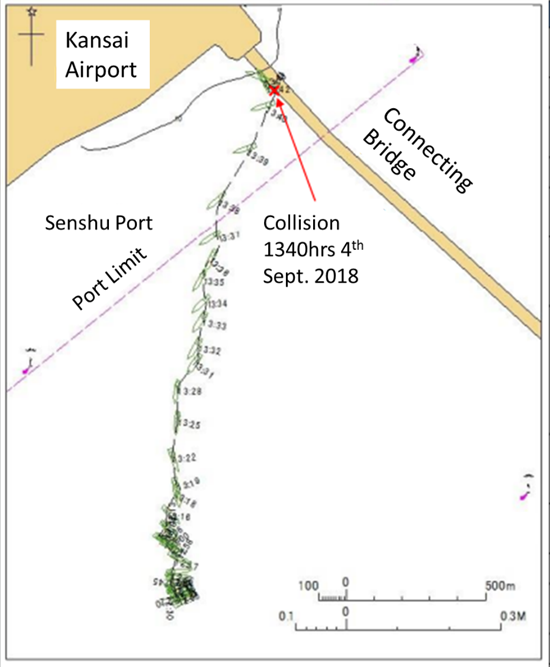

When a powerful typhoon passed directly over Osaka Bay on September 4, 2018, the tanker Houn Maru, which was anchored in the bay, dragged its anchor and eventually collided with the connecting bridge to Kansai International Airport. The impact severely damaged this bridge and prevented more than 5,000 people from leaving the island where the airport is located. The cost of repairs is believed to be approximately 5 billion yen and repair work was not completed until April 8, 2019.

The Houn Maru (2,591 gross tons) was anchored using a single anchor (stockless anchor, seven shackles) about one mile from the connecting bridge for safety during the typhoon. Anchor dragging started at about 13:00 when the wind was more than 50 meters/second. The ship’s fastest speed in relation to shore was 6.1 knots and the collision occurred at 13:40.

After examining this accident, the Japan Transport Safety Board identified the following items as measures for preventing this type of incident during extremely strong typhoon winds.

- The use of two anchors (instead of one) is generally recommend in these weather conditions, to provide greater strength to hold the ship in place.

- Use of the engine

- Selection of the anchorage location

- Receipt of weather and sea condition information etc.

Figure 1 - Movement of the Houn Maru while dragging anchor1

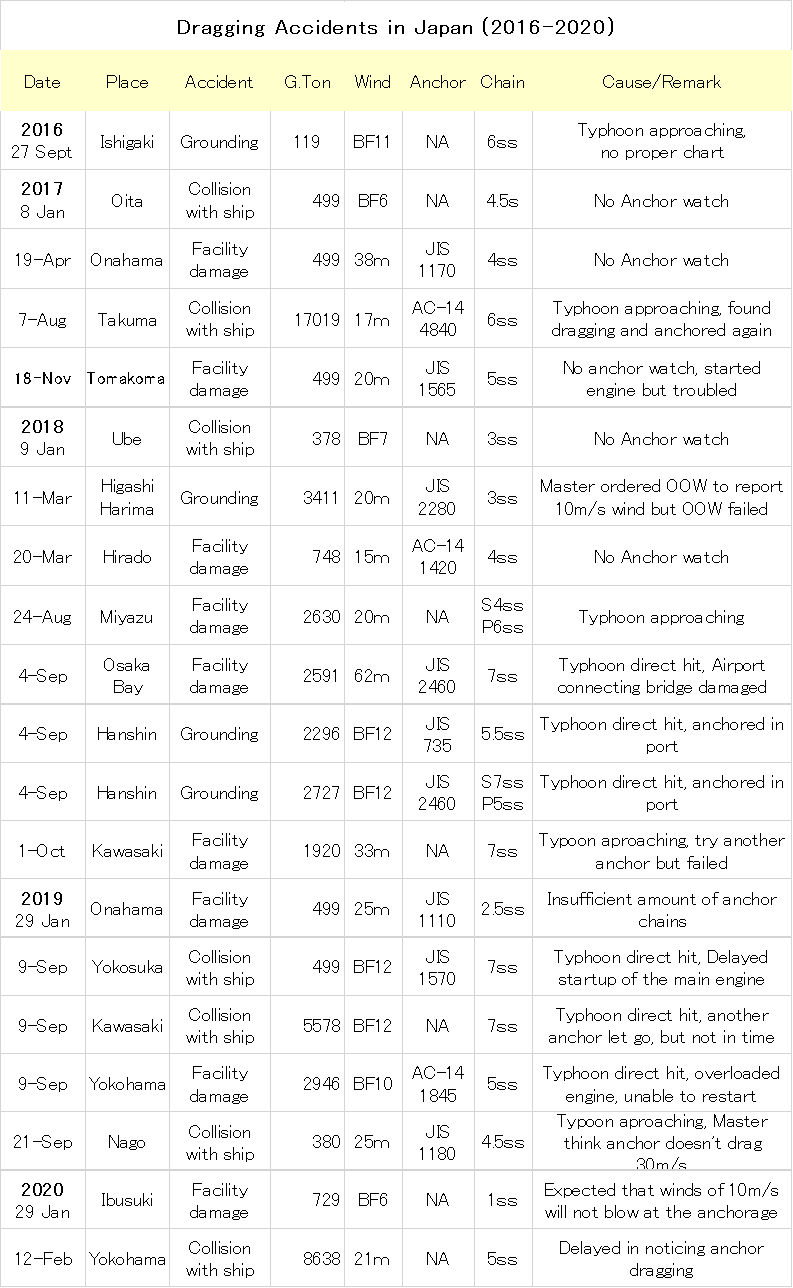

This type of anchor dragging incident occurs every year in Japan due to the frequency of typhoons. This report examines anchor dragging accidents in Japan during the five-year period from 2016 to 2000, in order to study the causes and consider preventive measures.

Table 1 - Dragging Accidents in Japan (2016-2020)1

Analysis

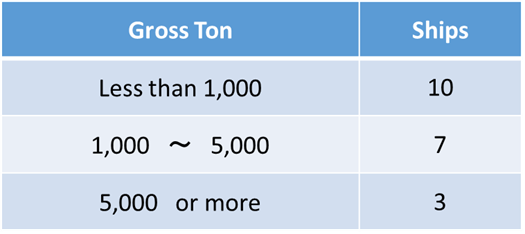

1) Size of ships that dragged the anchor (only ships of at least 100 gross tons)

Table 2 divides the accidents into three categories based on gross tonnage. Ships of less than 1,000 tons accounted for half of all accidents. Japan has a very large number of ships operating on domestic routes and these ships usually anchor in a harbor or bay for safety during a storm. This is probably the reason for this gross tonnage breakdown of anchor dragging accidents.

Table 2 - Anchor Dragging and Gross Tonnage

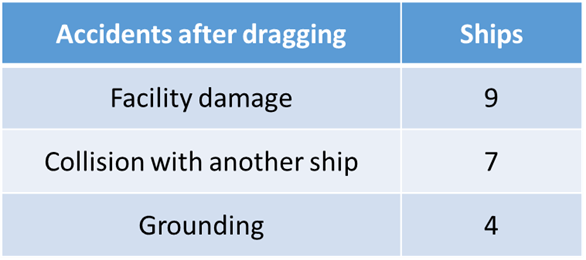

2) Accidents caused by dragging

Facility damage comprises almost half of damages that result from anchor dragging. Facilities include wharfs and wharf structures, buoys and other navigation aids. As was explained in the preceding section 1), relatively small ships account for a large share of dragging accidents. Since these ships usually anchor as far into a harbor or bay as possible for safety, anchor dragging often causes damage to nearby structures.

Table 3 - Damage Caused by Anchor Dragging

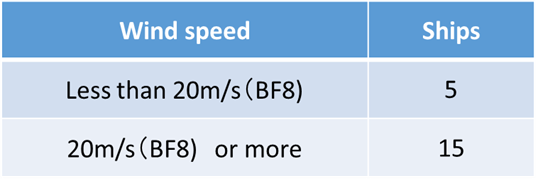

3) Wind speed during anchor dragging

The majority of accidents occur when the wind speed is more than 20 meters/second. We can therefore conclude that there is a very significant risk of dragging when the wind speed surpasses this level. Furthermore, accident data shows there is a risk of anchor dragging at lower wind speeds too.

Table 4 - Wind Speed during Anchor Dragging

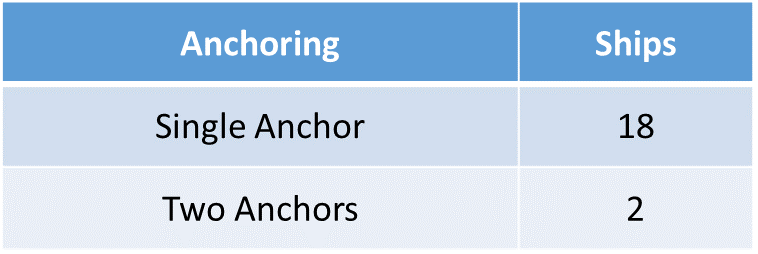

4) Anchoring methods

Most of the ships in this report were using a single anchor, and only two ships were held in place by two anchors. Two anchors are generally recommended because they provide much greater strength to hold a ship in place when the wind is strong. Nevertheless, the direction of the wind is constantly shifting during a typhoon. Changes in wind direction can cause anchor chains to become fouled when two anchors are used. Consequently, the use of two anchors is not necessarily better in all instances. This risk of fouled chains is why the master of the Houn Maru decided to use one rather than two anchors. The anchoring method is determined by carefully considering the current conditions.

Table 5 - Anchoring Method

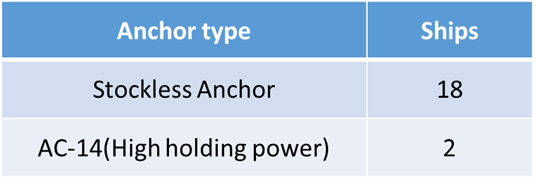

5) Types of anchors

Most of the ships that dragged their anchors were using a stockless anchor. Only two ships were using a high holding power AC-14. Although the AC-14 has been used by most large ships in recent years, the use of this anchor on smaller ships as well needs to be considered.

Table 6 - Anchor Type

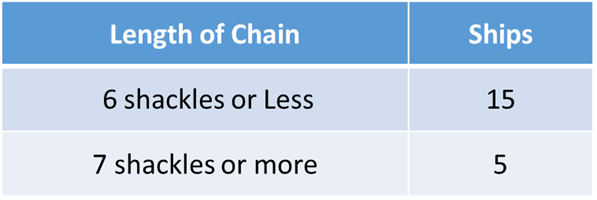

6) Length of chain

The majority of the ship accidents in this report involved the use of no more than six shackles. However, this length cannot be expected to provide sufficient holding power. The anchor plays a critical role due to the need to maintain the greatest possible holding power during very high winds. Consequently, the length of the chain must be determined in accordance with current weather and sea conditions.

Table 7 - Length of Chain (1 shackle = 27.5 meters)

Causes and preventive measures

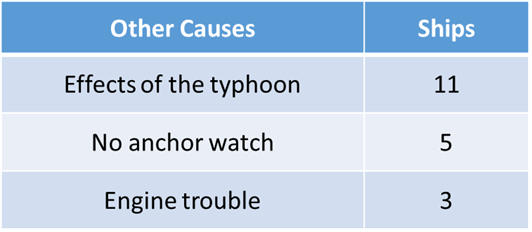

1) Other causes (Table 8)

The information in this report reveals that many ships had problems involving the anchoring method (selection of location and achieving sufficient holding power) during high winds. In addition, the ship’s master and other crew members apparently underestimated the force exerted on the ship by very strong wind.

Moreover, as is also shown in Table 8, the majority of anchor dragging accidents happen during a typhoon because of the frequency of these storms in Japan. As a result, when a typhoon is approaching, a ship’s crew must carefully examine the path and likely effects of the storm in order to select a suitable evacuation method (anchoring, riding out the storm by drifting at sea, moving to a location outside a harbor, etc.).

Furthermore, for five of the accidents in this report there are no anchor watches after anchoring, and this is common practice in small ships. Apparently, the crew members of small ships firmly believe there is no reason to worry when anchored in a harbor. However, caution is needed during high winds.

Use of the main engine is the most effective way to respond to anchor dragging. Unfortunately, there are some instances where this is not possible because of engine trouble. Obviously, a ship’s main engine must be constantly ready to be started when anchored during a typhoon or other storms that produces strong winds.

Table 8 - Other Causes

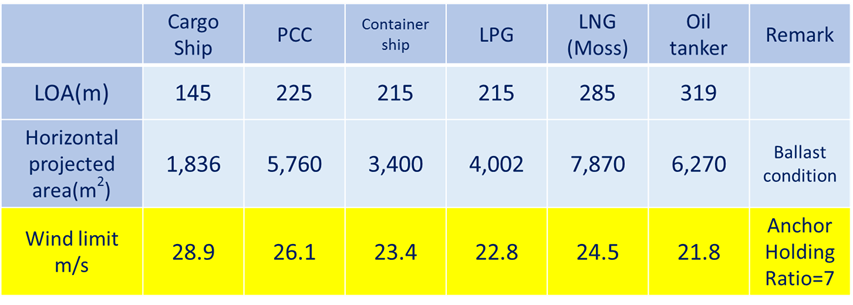

2) Maximum wind speed for safe anchoring

When a ship’s crew decides to anchor the ship during a typhoon or other storm that produces strong winds, the crew must know the maximum permissible wind speed for anchoring the ship. This wind speed can be calculated by using ship data (anchor holding power and other information) and external forces (wind force, strength of waves and other forces). The crew must determine the maximum permissible wind speed before anchoring the ship. Once external forces overcome the anchor holding power, it will no longer be possible to anchor the ship for safety during a storm.

However, calculating a precise number is difficult and the crew calculated an approximate figure by using a formula based on experience. Consequently, as the data in this report demonstrates, a ship’s crew must be aware of the risk of anchor dragging when the wind speed exceeds 20 meters/second.

To provide additional information, this report includes Table 9 to show the maximum permissible wind speeds for different types of ships according to study of professor Honda2 . Although the table covers many types and sizes of ships as well as different anchors, the maximum wind speed is mostly between about 21 and 25 meters/second.

When this strong wind is forecast, the crew must be vigilant when anchoring the ship and consider other ways (moving sufficiently offshore, drifting, etc.) to evacuate and ride out the storm safely.

Table 9 - Wind Speed Limits for Anchoring2

References

1) Japan Transport Safety Board Accident Report

2) Introduction to Ship Operation (Keinosuke Honda, Seizando Shoten Publishing)