Lessons Learnt: Death of an Engine Rating

13/04/2023

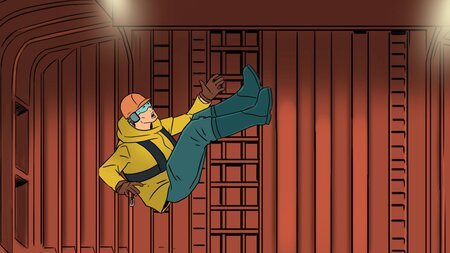

Lessons Learnt: Fall in Cargo Hold

16/06/2021

Lessons Learnt: Wet Damage to Cargo of Maize

08/04/2021

Lessons Learnt: Burn Injury to Engineer

08/01/2021

Lessons Learnt: Serious Injury to Pilot

14/08/2020

Lessons Learnt: Enclosed Space Fatality

05/06/2020

Lessons Learnt: Mooring Injury

16/04/2020

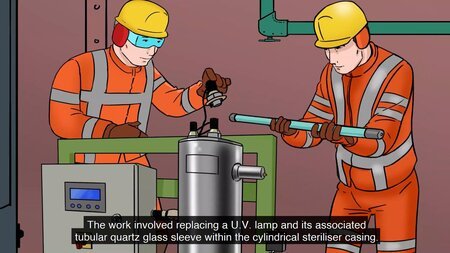

Lessons Learnt: Eye Injury to Fitter

31/01/2020

Lessons Learnt: Bunker Spill

18/06/2019